What Does Inventory Management Do?

Inventory management is the orchestrated process of ordering, storing, using, and selling a company's inventory. This includes raw materials, components, and finished products, as well as warehousing and processing.

Understanding the 4 Types of Inventory

Inventory is typically divided into four main types: raw materials, work-in-progress (WIP), merchandise and supplies, and finished goods. These classifications help businesses manage and track items in stock or those needed in the future.

Major Inventory Management Techniques

Three main inventory management strategies are pull, push, and Just in Time (JIT). Understanding these techniques helps businesses operate more efficiently and manage their inventory effectively.

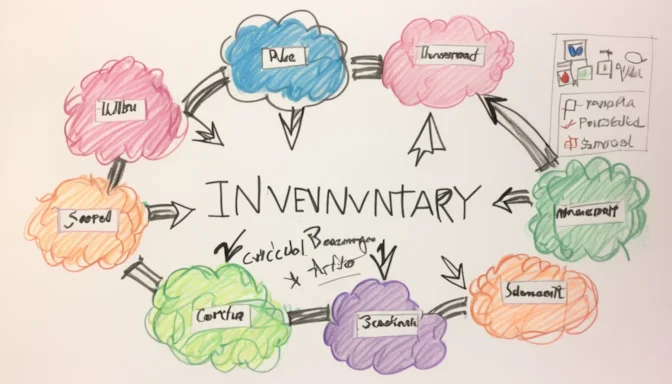

The Complexities of Inventory Management

Inventory management isn't just physically demanding; it requires coordination between various departments. Managers need to synchronize activities between the sales floor, office, stock room, and warehouse.

How to Calculate Inventory

Calculating ending inventory involves the formula: Beginning Inventory + Net Purchases - Cost of Goods Sold (COGS) = Ending Inventory. Grasping this basic equation is key for effective inventory management.

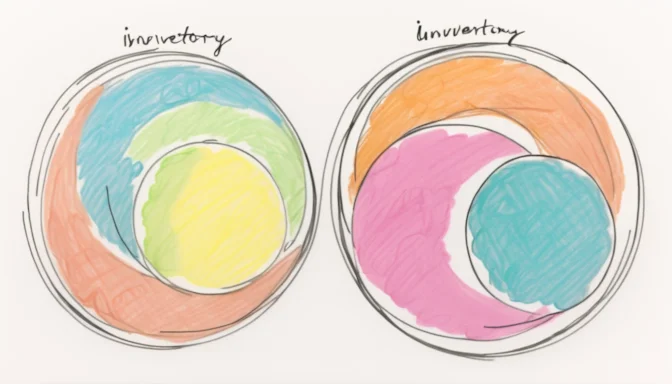

Differences Between Inventory and Stock

While all stock is considered inventory, not all inventory is stock. Stock refers to finished goods ready for sale, whereas inventory includes both finished goods and the components to create them.

The First Rule of Inventory Management

The primary rule is to have sufficient inventory to meet demand. Businesses should aim to avoid backorders and ensure items are readily available for customers.

First Steps in Inventory Management

The first step is data management. Creating, understanding, and organizing your inventory data is crucial in today’s data-driven business landscape.

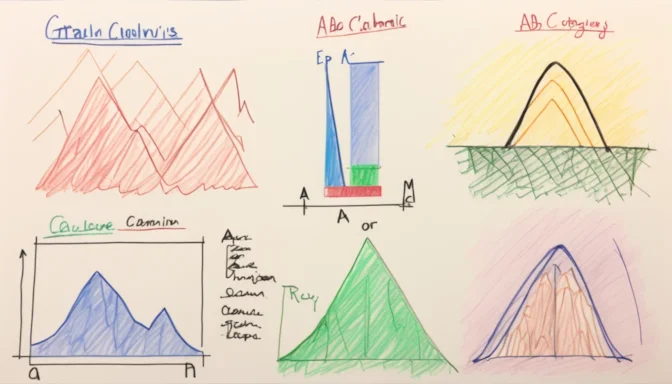

What is ABC Analysis?

ABC analysis is an inventory management technique that ranks items based on their business importance. This method helps inventory managers efficiently group items.

Four Ways to Control Inventory

Common methods for control include ABC analysis, Last In, First Out (LIFO) and First In, First Out (FIFO) systems, batch tracking, and maintaining safety stock.

E-Commerceo

E-Commerceo